Hydraulic Cylinder Manufacturer And Hydraulic Cylinder Supplier

Teutonic is a well-established supplier of Hydraulic cylinders and Hydraulic systems to leading OEMs of Indian industries, offering complete Hydraulic solutions to various industry verticals at the most competitive prices.

We, Teutonic manufacturer and suppler of precision engineered hydraulic cylinders of superior quality in the shortest lead-time. At every stage of our business operations, we maintain an unwavering dedication to upholding quality, enabling us to excel in our field. From the utilization of premium-grade raw materials to rigorous inspections of our final products, we prioritize the highest standards.

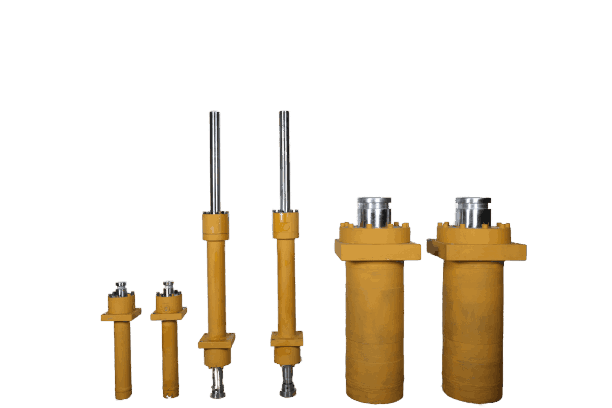

As industry pioneers, we proudly provide a diverse range of hydraulic cylinders, including bolted cylinder hydraulic, industrial hydraulic cylinder, tie rod cylinders, and welded hydraulic cylinder, all originating from India.

Hydraulic Cylinder

Product Details

Bore size 32 to 400 mm

| Maximum Pressure | 250 bar |

| Rod Diameter | 16-250 |

| Max. Stroke | 5000mm |

| Mounting Style | Front Flange,Foot Mounting,Clevis |

| Temperature | 80 Deg C |

| Material | Steel |

| Chrome Layer Thickness | 10-30 micron |

Bolted Cylinder Hydraulic

Product Details

Bore size 32 to 400 mm

| Maximum Pressure | 250 bar |

| Rod Diameter | 16-250 |

| Max. Stroke | 5000mm |

| Mounting Style | Front Flange,Foot Mounting,Clevis |

| Temperature | 80 Deg C |

| Material | Steel |

| Chrome Layer Thickness | 10-30 micron |

Usually Bolted Cylinder to the cylinder barrel. Our Piston Seals are designed to facilitate easy removal of the piston rod assembly and rod seals for servicing purposes.

Milled Type Cylinder

Product Details

Bore size 32 to 400 mm

| Maximum Pressure | 250 bar |

| Rod Diameter | 16-250 |

| Max. Stroke | 5000mm |

| Mounting Style | Front Flange,Foot Mounting,Clevis |

| Temperature | 80 Deg C |

| Material | Steel |

| Chrome Layer Thickness | 10-30 micron |

Tie Rod Cylinders

Product Details

Bore size 32 to 400 mm

| Maximum Pressure | 250 bar |

| Rod Diameter | 16-250 |

| Max. Stroke | 5000mm |

| Mounting Style | Front Flange,Foot Mounting,Clevis |

| Temperature | 80 Deg C |

| Material | Steel |

| Chrome Layer Thickness | 10-30 micron |

Tie Rod Cylinders utilize threaded steel rods with high strength, effectively securing the two end caps to the cylinder barrel. Industrial factory applications commonly feature these types of cylinders. Smaller bore cylinders typically incorporate four tie rods, while larger bore cylinders may necessitate the use of 16 or 20 tie rods to securely hold the end caps in place.

Welded Hydraulic Cylinder

Product Details

Bore size 32 to 400 mm

| Maximum Pressure | 250 bar |

| Rod Diameter | 16-250 |

| Max. Stroke | 5000mm |

| Mounting Style | Front Flange,Foot Mounting,Clevis |

| Temperature | 80 Deg C |

| Material | Steel |

| Chrome Layer Thickness | 10-30 micron |

Welded Hydraulic Cylinder have no tie rods. The barrel is directly welded to the end caps, providing a strong connection. The ports are welded to the barrel, ensuring a secure attachment. In most cases, the front rod gland is threaded into or bolted to the cylinder barrel, allowing for easy removal of the piston rod assembly and rod seals for servicing purposes.

"Pinnacle Quality in Hydraulic Cylinders: Teutonic Hydraulics, Your Reliable Manufacturing and Supply Partner"

In the realm of hydraulic systems, finding a reliable and proficient manufacturer and supplier is paramount to the success of your operations. Teutonic Hydraulics stands as a trusted name in the industry, offering top-notch hydraulic cylinders that epitomize performance and durability. This article delves into the myriad benefits of choosing Teutonic Hydraulics as your hydraulic cylinder manufacturer and supplier.

Unparalleled Expertise:

Teutonic Hydraulics boasts a wealth of experience in the hydraulic industry. With a proven track record, the company has designed and produced hydraulic cylinders for diverse applications, showcasing their unmatched expertise and dependability.

Tailored Customization:

Recognizing the uniqueness of each hydraulic system, Teutonic Hydraulics offers tailor-made solutions to cater to your specific needs. From dimensions and designs to mounting styles and pressure capacities, the company's versatility ensures your requirements are met to the finest detail.

Commitment to Quality:

Aligned with industry standards, Teutonic Hydraulics adheres to stringent quality control processes. Certified with ISO 9001, their commitment to producing high-caliber hydraulic cylinders is evident, guaranteeing performance excellence and longevity.

Premium Material Selection:

Materials wield considerable influence over hydraulic cylinder performance. Teutonic Hydraulics diligently selects materials tailored to your application's demands, considering variables such as temperature, pressure, and environmental factors.

Rigorous Testing and Inspection:

Prior to dispatch, Teutonic Hydraulics subjects each hydraulic cylinder to rigorous testing and inspection. This meticulous scrutiny ensures cylinders meet performance benchmarks and are devoid of defects.

Unmatched Technical Support:

At Teutonic Hydraulics, impeccable technical support is a cornerstone. The company stands by your side during selection, installation, and troubleshooting, offering expertise that is invaluable for seamless operations.

Punctual Delivery:

Timely delivery is a core tenet at Teutonic Hydraulics. Recognizing the significance of minimizing downtime, the company prides itself on its record of punctual and reliable delivery.

Customer Testimonials:

Glowing customer reviews and feedback underscore the reliability and quality of Teutonic Hydraulics. Their satisfied clientele attests to the company's dedication to customer satisfaction.

Value-Driven Pricing:

While pricing is a factor, Teutonic Hydraulics emphasizes overall value. Opting for a company that offers high-quality cylinders may entail a slightly higher cost upfront but pays dividends in terms of minimized maintenance and prolonged cylinder life.

Comprehensive After-Sales Support:

Teutonic Hydraulics extends comprehensive after-sales support, including warranties and troubleshooting assistance. This commitment ensures your peace of mind long after the initial purchase.